- +91 94260 15205

- nisargcasting@gmail.com

At Nisarg Casting, we have built our reputation on quality. It is fundamental that a business enterprise exists only because of its satisfied customers. The reputation of Nisarg Casting, reflected in the dedication of our people and our ex-panding list of customers, has been built by consistently producing castings to their exact specifications.

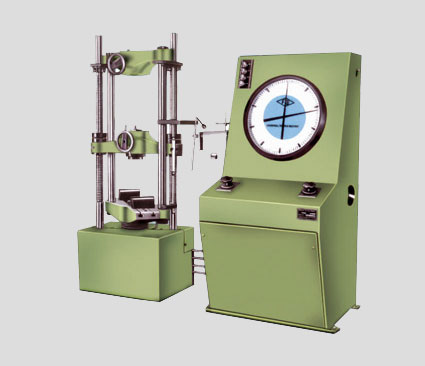

In combination with our experienced, dedicated staff, control of quality is accomplished by using the most modern and exacting laboratory equipment available.

Before a heat of metal is poured it must first pass a rigid quality inspection. A test sample or “button” is taken from the heat before it is poured. A modern optical emission spectrometer is used to perform a complete chem-ical analysis. The chemical analysis is part of the step-by-step quality check routine to insure that each casting meets our customer’s specifications. Each “button” is tagged, cross-referenced and retained for future refer-ence.

Each casting is permanently marked with our work order number, heat number and type of material to insure product traceability throughout the manufacturing process.

Each casting sample is also under go for its mechanical property check as per its standard.