Brass Casting

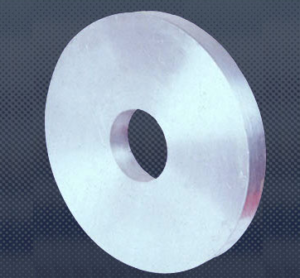

Brass centrifugal casting parts, sleeve, bush, bearing bushing, Suited for high load, low-speed application. The product’s copper sleeve could be in different specifications and sizes. We could make any like this item according to your requirement, it will use in plastics extruder machine. The feature of it will be a smooth surface, free from pinhole porosity, hard wearing, long useful time. Material: copper and another nonferrous alloy.Sizes range(mm): according to your demand.Tolerance:0.01-1mm.

| BRASS GRADE | Cu | Sn | Pb | Zn | Fe | Ni | P | Al | Mn | Si | Sb | Imp |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Brass IS:8631-1977 Grade-2 | 55 | 1 | 0.5 | Rem. | 0.7-2 | 1 | - | 0.5-2.5 | 3 | 0.1 | - | - |

| IS:292-1983 LCB-1 | 70-77 | 1.3 | 2-5 | Rem. | 0.5 | - | - | 0.01 | - | - | - | - |

| IS:292-1983 LCB-2 | 63-67 | 1.5 | 1-3 | Rem. | 0.5 | - | - | 0.01 | - | -- | - | - |

| High Tensile Brass IS:304-1981 HTB-1 | 55 min | 1 | 0.2 | Rem. | 0.7-2 | - | - | 0.5-2.5 | 3 | 0.1 | - | 0.2 |

| High Tensile Brass IS:304-1981 HTB-2 | 55 min | 0.2 | 0.2 | Rem. | 1.5-3.25 | - | - | 3-6 | 4 | 0.1 | - | 0.2 |

| Silicon Brass(Grade-1) | 79 min | - | 0.5 | 12.5-16 | 0.3 | - | - | 0.5 | - | 3.2-5 | - | 0.5 |

| Silicon Brass(Grade-2) | 88 min | - | 0.5 | 4.5-7 | 0.3 | - | - | - | - | 3.7-5.5 | - | 0.5 |

| Silicon Brass(Grade-3) | 80-83 | - | 0.4 | Rem. | 0.3 | - | - | 0.05 | - | 4.1-4.7 | - | 0.5 |

Aluminium Bronze Casting

Aluminum bronzes contain varying amounts of aluminum, usually ranging from 5 to 11 percent. Other metals, such as copper, iron, nickel, manganese, and silicon, are added to enhance the mechanical and physical properties.

Aluminum bronze offers some valuable characteristics, including:

- high strength

- excellent corrosion and wear resistance

- high thermal and electrical conductivity

- non-sparking benefits

APPLICATIONS Product Category Product Automotive Weld Guns Fasteners Large Hold Down Screws Nuts Industrial Bearing Segments for the Steel Industry Bearings Gears Machine Parts Pawl Pickling Hooks Pressure Blocks for the Steel Industry Pump Parts Spur Gears Valve Bodies Valve Seats Valves Worm Gears Marine Covers for Marine Hardware Ship Building Ordnance Government Fittings

It is a popular choice for many industrial applications, ranging from landing gear components on aircraft through to ship propellers and even jewelry.

| GRADE | Cu | Sn | Pb | Zn | Fe | Ni | P | Al | Mn | Si | Imp. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| AB-1 or C95400 | Rem. | 0.10 | 0.03 | 0.5 | 1.5-3.5 | 1 | - | 8.5-10.5 | 1 | 0.25 | 0.3 |

| AB-2 or C95500 | Rem. | 0.1 | 0.03 | 0.5 | 4-5.5 | 4-5.5 | - | 8.8-10 | 1.5 | 0.1 | 0.3 |

| C95300 | 86 min | - | - | - | 0.8-15 | - | - | 9-11 | - | - | - |

| IS:3091-1963 | Rem. | - | - | - | 4-5 | - | - | 9-11 | 0.1-0.5 | - | - |

| IS:8631-1977 Grade 1 | Rem. | 0.1 | 0.05 | 0.5 | 4-5.5 | 4-5.5 | - | 8.8-10 | 1 | 0.1 | - |

Phosphorous Bronze Casting

Our range of Phosphor Bronze Castings is widely demanded for features like high strength, low coefficient of friction and fine grain. The range of Phosphor Bronze Castings is appreciated in the market for its features of perfect finish, modular design and smooth edges. Clients can avail the Phosphor Bronze Castings in customization with the details specified by them. Phosphor Bronzes PB1, PB2, PB3 & PB4 are predominantly used for their wear resistance and bearing properties. Bronzes PB1 and PB2 are preferred in the form of heavy duty gears, worm-wheels and bearings for the more critical applications where high working loads, high speeds, impact loading and pounding coupled with adequate lubrication and good alignment are found. Phosphor Bronze PB4 is adequate for the less critical applications. Phosphor Bronze Castings are extensively used in diversified industrial sectors.

Highlights

- Dimensional accuracy

- Easily Affordable Prices

- Durability

- Rust-proof

- Copper Tin alloys with about 0.4-1% phosphorus are harder than tin bronzes but with lower ductility

| GRADE | Cu | Sn | Pb | Zn | Fe | Ni | P | Al | Mn | Si | Imp. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| PB-1 | Rem. | 10 min | 0.25 | 0.05 | 0.1 | 0.1 | 0.5 min | 0.01 | - | 0.02 | 0.6 |

| PB-2 | Rem. | 11-13 | 0.5 | 0.3 | 0.15 | 0.5 | 0.15 min | 0.01 | - | 0.02 | 0.2 |

| PB-4 | Rem. | 9-5 min | 0.75 | 0.5 | - | 0.5 | 0.4 min | - | - | - | 0.5 |

| Tin Bronze IS:1458-1965 Ph. Bz. Class-1 | Rem. | 6-8 | 0.5 | 0.5 | 0.3 | - | 0.4-0.6 | 0.01 | - | - | 0.6 |

Copper EC Grade Casting

We have been committed to manufacture and supply quality assured Copper EC Grade Casting.

With require parameters like conductivity and purity and impurity free heavy and small casting.

The major uses of pure, unalloyed copper are based on its high electrical and thermal conductivity as well its good corrosion resistance. Almost all alloying elements are detrimental to the electrical conductivity of copper, making the purity of the metal an important issue. Commercially pure copper is represented by UNS numbers C10100 to C13000. The various grades of unalloyed copper differ in the amount of impurities and therefore do behave differently. Oxygen free coppers are used in applications requiring high conductivity and exceptional ductility.

Gun Metal Casting

We are among the prominent Gun Metal Castings Manufacturers and Suppliers all over India. Gun Metal Castings brought forth by the company, are available in various hardness, tensile strengths and dimensions. Gun Metal Castings are manufactured using high grade raw materials in compliance with international quality standards. Gun Metal Castings of our company are widely accepted in different industries for their quality. Gun Metal Castings are highly appreciated by clients for their tolerance capacity, dimensional accuracy and durability. Typical uses of Gunmetal Casting is Pressure tight bearings, bushes, pumps and pump fittings, valves, valve bodies, and valve guides under corrosive marine conditions, Gear and worm wheels, Bearings for aero engines, diesel engines, electrical generators and rolling mills etc.

Attributes

- Easily affordable prices

- Corrosion resistant finish

- High tensile strength

- Longer service life

- Various Hardness

- Dimensions Accuracy

- Tolerance Capacity

| GRADE | Cu | Sn | Pb | Zn | Fe | Ni | P | Al | Mn | Si | Imp. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| LTB-1 | Rem. | 6-8 | 2.5-3.5 | 1.5-3 | 0.3 | 2 | - | 0.01 | - | 0.01 | 0.7 |

| LTB-2 | Rem. | 4-6 | 4-6 | 4-6 | 0.35 | 2 | - | 0.01 | - | 0.02 | 0.8 |

| LTB-3 | Rem. | 6-8 | 9-11 | 0.75 | 0.35 | 2 | - | 0.01 | - | 0.02 | 0.8 |

| LTB-4 | Rem. | 6-8 | 14-16 | 0.75 | 0.35 | 2 | - | - | - | 0.02 | 0.8 |

| LTB-5 | Rem. | 9-11 | 8.5-11 | 1 | 0.35 | 2 | - | 0.01 | - | 0.02 | 0.8 |

| LTB-6 | Rem. | 4-6 | 18-23 | 1 | 0.35 | 2 | - | - | - | 0.01 | 0.8 |

Aluminium Casting

We offer a various range of aluminium casting of up 1000 mm dia for various industries like oil and Gas industries, heavy machine manufacturing industries, special ring for light weight application.

Zinc Die & Centrifugal Casting

We offer a Die & Centrifugal Casting in pure Zinc metal.

Zinc being the easiest alloy to cast, offers high ductility and good impact strength. It can also be easily plated. Thus making zinc die casting economical for small parts like building hardware, buttons and luggage fittings, electrical switchgear parts and decorative artware.

Centrifugal casting offers higher quality in the field of material strengths, casting accuracy and better reproduction of details. It gives high quality parts from common commercial zinc alloys. Centrifugal casting offers an alternative solution to the diecasting technology.

Cylinder Liner & Sleeves

Cylinder Liners – Sleeves, made of grey cast-iron, ought to have desired casting and machining qualities, viz. strength, toughness, hardness and wear resistance. These are mainly of two types Dry liner-sleeves and Wet liner-sleeves.

Dry Liner

It is in direct contact with engine block. The outer diameter is very precise and perfect without contours.

Wet Liner

It comes with sealing grooves for ‘O’ rings and is always in direct contact with water. A wet liner is generally heavy and thick walled.