- +91 94260 15205

- nisargcasting@gmail.com

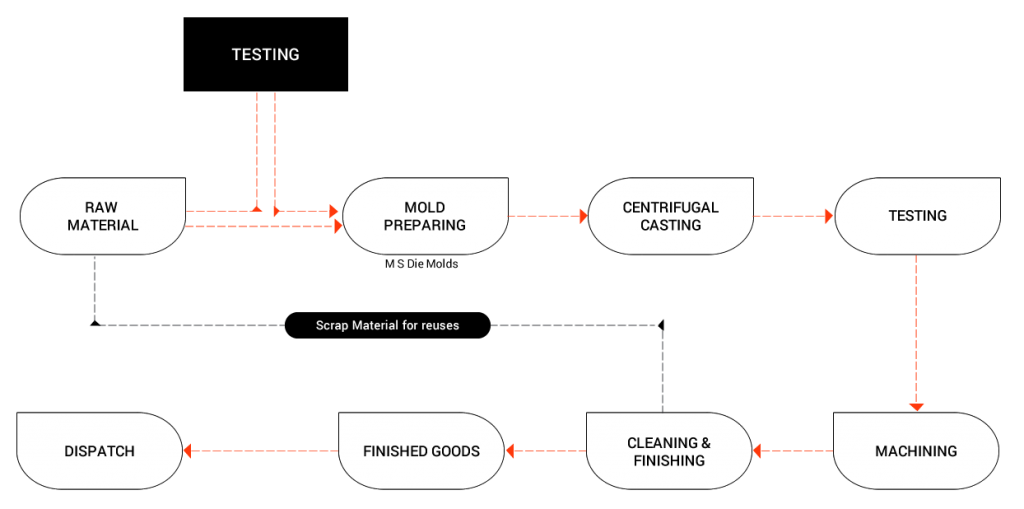

NISARG CASTING is the partnership firm incorporate in 2009 with common objective of manufacturing of Alloy Castings & Industrial Ingots.

Our range includes Non Ferrous Centrifugal Castings for Aluminum Bronze Alloy Casting, Brass Ingots Casting, Lead Bronze Alloy Casting, Brass Alloy Casting, Phosphorus Bronze Alloy Casting, Copper Alloy Casting, Gun Metal Alloy Casting, Copper Nickel Alloy Casting, Bronze Ingots Casting, Aluminium Centrifugal Casting and Tin Bronze Alloy Casting.

We boast proven management techniques, up-to-date manufacturing methods, and technology in the production of high quality centrifugal castings.

Numbered among our customers are some of the largest and most sophisticated companies in the country. Our satisfied customers are often our best salesmen because they enthusiastically recognize the benefits of high quality combined with dependable customer service.

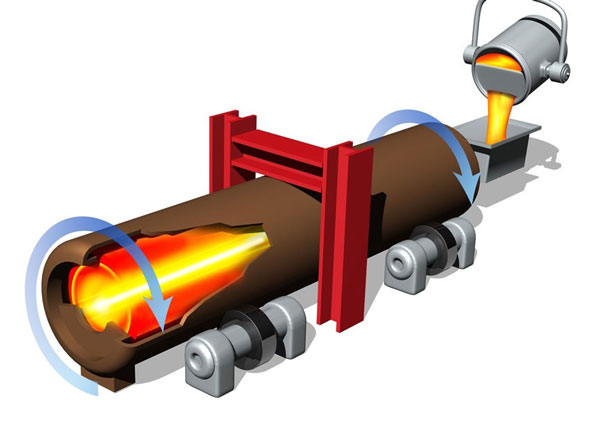

Centrifugal castings are sometimes referred to as liquid forgings. The centrifugal casting process is unlike other foundry processes in that it requires special knowledge, practices and skills not usually found in other types of foundry operations. In the centrifugal casting process, molten metal is poured into a hollow cylindrical mold spinning about a horizontal or vertical axis at speeds generating more than 100 Gs of centrifugal force. The centrifugal force distributes the molten metal and shapes it into a tubular casting.

Improved Physical Properties formed under pressures many times that of gravity combined with directional solidification, two unique characteristics of the centrifugal casting process, parts made from centrifugals exhibit a denser, closer grained structure with vastly improved physical properties. Because of high structural uniformity, physical properties such as tensile strength, yield strength, elongation, reduction of area, and other desirable properties are improved by up to 30% over conventional gravity or static casting methods.

Longer LifeParts made from centrifugals, with the castings’ finer grained, denser structure provide increased service life and withstand greater overloads and impact without fracturing.

Reduced Rejects As the molten metal is poured, centrifugal forces distribute the molten metal against the walls of the mold with tremendous force, thereby displacing the lighter oxides and impurities, causing them to surface on the inside diameter of the hollow cylinder being cast. The trapped oxides and impurities are easily removed in the machining process.

Pattern Expense EliminatedThe extensive inventory of molds available at CCI eliminate the customer’s expense of buying, storing, maintaining and insuring patterns.

Reduction of Manufacturing Costs as a result of the uniformity and other desirable characteristics of centrifugal castings, machining time and material waste are significantly reduced. Hard spots, sand residue, cavities, blowholes and porosity are virtually eliminated.

Production Flexibility The centrifugal process allows economical production of a diversified range of sizes, shapes and quantities.

Faster Delivery Due to the short mold set up and preparation time required for centrifugal castings, delivery can be scheduled to meet the customer’s needs. The customer benefits from reduced manufacturing lead time and avoids the high cost of maintaining inventory.